Create Your First Project

Start adding your projects to your portfolio. Click on "Manage Projects" to get started

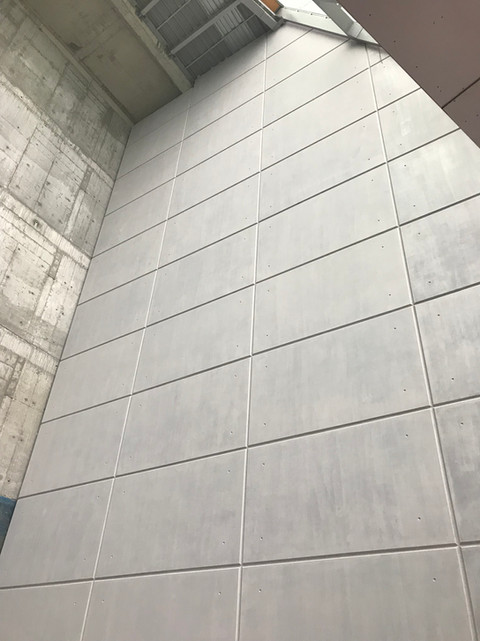

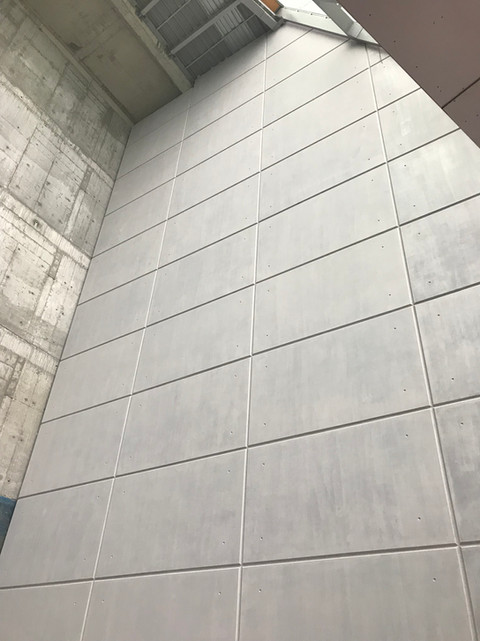

Pharmaceutical Factory - New Production Facility and Additional Buildings Precast (GRC) Projects

Location

Istanbul, Hadimkoy

Date

September 2021 - August 2024

Project type

Industrial

PROJECT SUMMARY

This comprehensive industrial project located in Hadımköy, Istanbul consists of three different structures within the same construction site: The new production facility of the pharmaceutical factory, the parking ramp wall, the stair walls and the warehouse building. The project has a large scale that requires detailed coordination of engineering and production processes, and meticulous planning has been made for the uninterrupted operation of the production lines. The production process was closely monitored simultaneously with the applications in the field and the coordination of all details was ensured. All field management and corporate communication were carried out by us from the first day of assembly to the painting process.

In these projects, all steps including proposal preparation, corporate meetings, application and production projects, workshop production process and logistics coordination to the field were carried out flawlessly. Daily technical support and field supervision were provided throughout the assembly process in the field, and progress in accordance with the construction site meetings and work schedule was guaranteed by us.

SERVICE SCOPE

Precast (GRC) detail solutions

Implementation project drawing

Production drawings and mold design

Production planning

Logistics and shipment coordination

Assembly projects

Daily field supervision and technical reporting

Corporate construction site coordination

TECHNICAL PROCESS

Start

In the project transferred to us for the new production facility, existing drawings were reconsidered and all detail solutions were optimized and the precast (GRC) application project was drawn. The revisions determined as a result of institutional meetings were integrated into the project.

Application Project

Precast (GRC) application projects were prepared for three structures. Plan, section and appearance sheets were detailed considering field conditions, ease of production and assembly process.

Production Drawings

The production order of all parts suitable for the mold cycle was determined. Technical details, connection and assembly points, and carrier system relations were processed completely.

Production Planning

The production process of the parts was planned by considering the workshop capacity, project schedule and shipment plans. Coordination was provided for them to reach the site ready for assembly after manufacturing.

Assembly

Site visits and team meetings were held before assembly. Assembly project, dimensioning and assembly strategies were determined and shared with the teams. Active field management was provided throughout the process, and daily, weekly and monthly reports requested by the employer were regularly delivered.

Coordination

Continuous contact was maintained with the manufacturer, field teams and the employer throughout the precast (GRC) process of all three structures. Site meetings, work schedule follow-up and technical support processes were managed by us.

Earnings Process

For all three sub-projects, quantity surveys, preparation and earnings tables were prepared in accordance with the formats requested by the employer. Attachment files (on-site manufacturing photographs, manufacturing sheets, work schedule comparisons, quantity survey printouts, etc.) were delivered completely. In accordance with the sensitive approval mechanisms of corporate companies, the process was followed in each earnings delivery and approval was received without any problems with complete documents. This process, which includes intensive procedures, was carried out without any disruption thanks to systematic and careful document management.