Precast Projecting Process

- Apr 12, 2025

- 2 min read

Updated: May 15, 2025

The first step to success in precast facade applications is the correct project design process. Aesthetics, functionality and applicability come together in the precast project process, forming the basis of all stages from design to assembly.

The precast project process begins with analysis of suitability for architectural design. The design of the structure is examined, and areas suitable for precast use on the facade are determined. At this stage, aesthetic concerns are balanced with technical requirements.

After area measurements, special application drawings are prepared for the structure. If necessary, land measurements are made using laser scanning or classical methods. This data is transferred to a digital environment to create a project infrastructure.

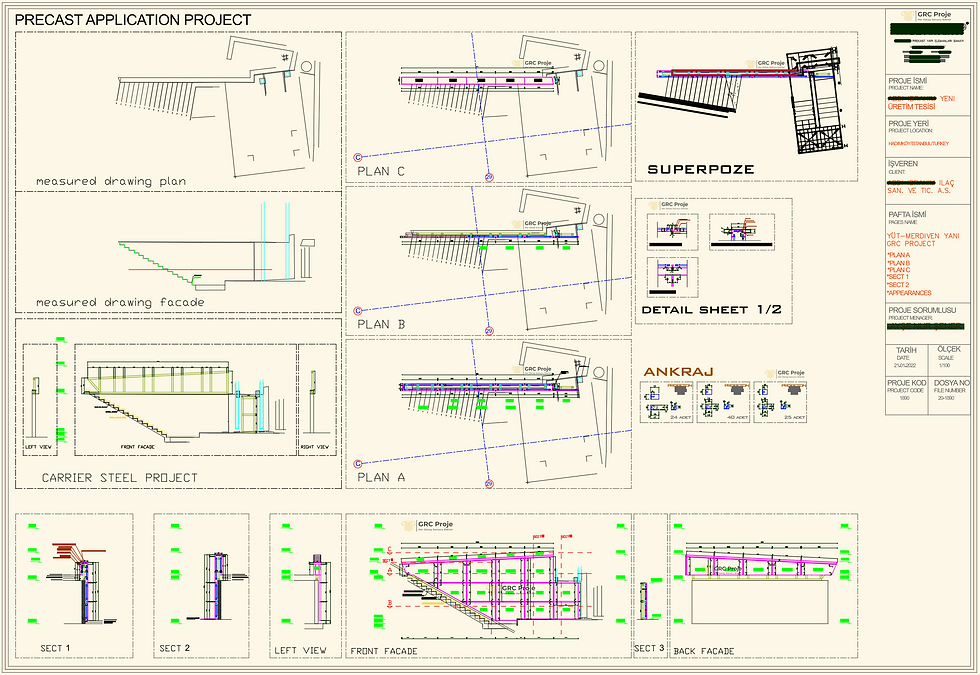

Detailed application sheets are prepared with plan, section and appearance drawings. This stage is very critical in terms of ease of assembly and production accuracy. System details are clarified. The entire project is completed in a way that the production parts can be removed. The Precast Assembly Project is prepared at the end of this stage in a way that is suitable for the assembly teams.

The technical specifications, dimensions and connection details of each panel are specified in the production drawings. These drawings, optimized according to the mold cycle, directly affect the workshop process. The photo on the side is one of the project-mold compatibility control shots in our mold making process.

The transportation, placement and connection details of the panels are determined. Solutions suitable for field conditions are developed by foreseeing the difficulties that may be encountered during the assembly process.

Communication is maintained with the production and assembly teams throughout the project process. Necessary revisions are made in line with feedback from the field, and all technical coordination of the process is maintained through workshop and field controls.

A properly planned precast project process not only facilitates production and assembly, but also reduces costs and saves time. We are with you in your projects with technical support, application experience and detail solutions. Contact us for a smooth application process.

Comments